Alright, so at the beginning of November I purchased a Springfield Armory M1A loaded, brand new from the local gun store for a good price. When it arrived I was like a kid in a candy store experiencing, or more accurately re-experiencing, every feature and feel of the gun. I purchased this with the Boyd Walnut stock to keep the "classic" look should I ever decide to sell this gun later on (unlikely, but just in case). I knew I'd never get what I wanted out of it with all the bits and bobs I'd tack on later! I also purchased a 50 round box of the CBC 7.62 NATO with 2015 production dates and the NATO cross on the bottom of the brass. I figured, if nothing else this should set the tone and expectations for the future of this rifle and give me a baseline of what to expect with some lack luster ammo.

Here she is as I bought her:

![Image]()

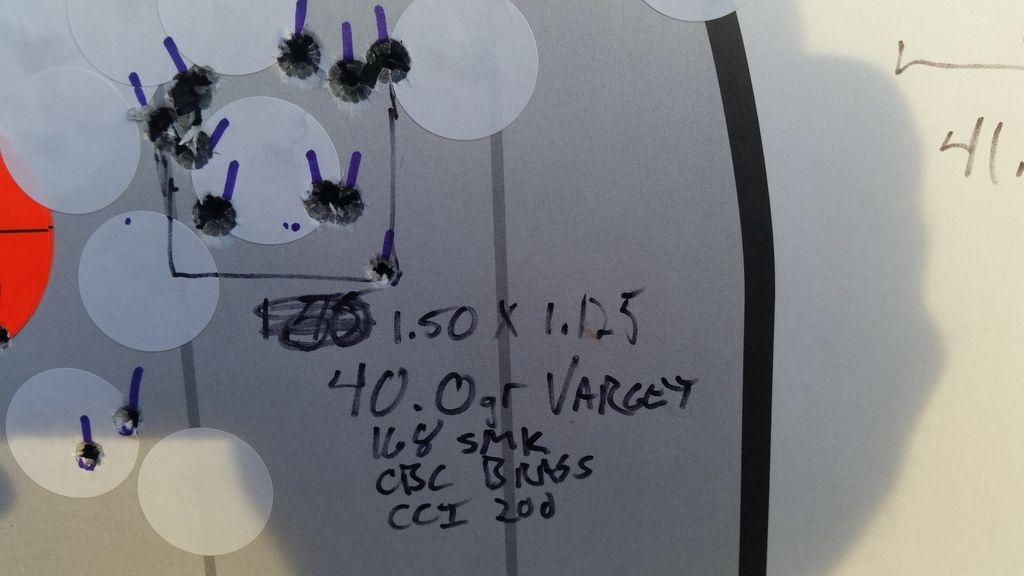

Now I've shot M1A's and Garands before so I'm pretty well versed in the sights, controls, take down and maintenance so the first order of business was to clean the barrel. Done! Next go to the range and sight it in! I was reading through the cool US Army manual that came with the M1A loaded and it said to dial up the elevation 8 clicks for a 100 yard zero... yeah, no. Try 18. No worries! The CBC rounds all went bang and formed up a rather impressively bad 4 MOA group (I feel this is excessive for a Loaded shooting military ball, but it's still minute of man till 300ish yards). Shot all 50 rounds, cleaned the gun up (dirty ammo!), bought 60 rounds of Winchester White Box "Match" (LOL) 7.62 NATO and shot again. 3.5 MOA.

Then my wallet cried! I knew what I wanted to do with this rifle long before I purchased it so I just made the leap and ordered a whole heap of parts I wanted to not only make it more accurate but improve ergo's some (not that the M14 isn't ergonomic in factory form).

Order went in and all this crap started showing up on my door over the past week!

Troy MCS Chassis

Magpul PRS Stock

Magpul MOE Grip

Yankee Hill Bipod Adaptor Plate

Harris 9-13" Bipod (non swivel, I'm a cheapass )

)

AUKMONT 45º BUIS (cheap, supposedly decent, if not, they'll get tossed)

Sparrowhawk Dummy Selector Lockout kit

Vortex Viper PST 6-24x50mm EBR1 Mil First Focal Plane (Not Pictured)

Vortex Tactical very high rings (yay?) (Not Pictured)

Checkmate Industries 20 round Mags w/ Magpul 7.62 Magpuls x3

Springfield Armory 10 round Mag

Sadlak Industries National Match Spring Guide

Fulton Armory Gas System Shim Kit

Just waiting on the optics to show up and then I might be done... Thinking about throwing the Sadlak Industries National Match gas piston in there too but we'll see how it shoots first when the optics get here.

And for the gun pr0n!

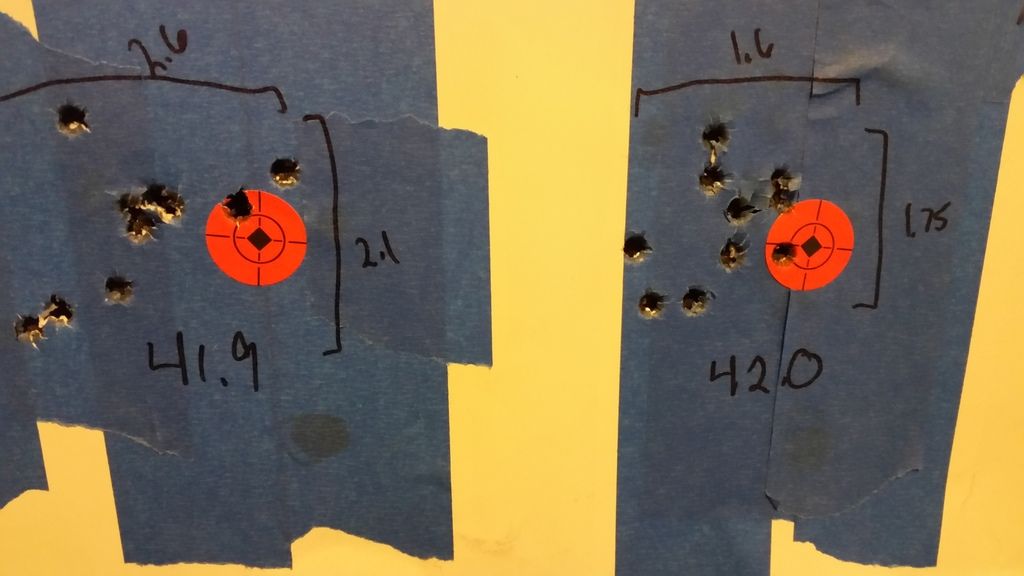

Vortex has been a bit slow in processing my order so I'm hoping that gets here before the end of the decade. I've got some more of the CBC to shoot from the same lot number as the first batch of 50. I'm praying for 2 MOA in this configuration with military ball. I've also loaded up some hand loads using 168gr SMK's and 175gr SMK's (my favorite rounds!) on top of some Varget (kept the loads pretty low, knowing this is a less than ideal powder for M1A's) in the Winchester and CBC NATO cases. I have some comercial Winchester brass around here too that I'll eventually load up and let the brass muncher work it's magic on them. I can't wait for the scope to get here though so I can do more shooting!

Stay tuned for "more"!

Here she is as I bought her:

Now I've shot M1A's and Garands before so I'm pretty well versed in the sights, controls, take down and maintenance so the first order of business was to clean the barrel. Done! Next go to the range and sight it in! I was reading through the cool US Army manual that came with the M1A loaded and it said to dial up the elevation 8 clicks for a 100 yard zero... yeah, no. Try 18. No worries! The CBC rounds all went bang and formed up a rather impressively bad 4 MOA group (I feel this is excessive for a Loaded shooting military ball, but it's still minute of man till 300ish yards). Shot all 50 rounds, cleaned the gun up (dirty ammo!), bought 60 rounds of Winchester White Box "Match" (LOL) 7.62 NATO and shot again. 3.5 MOA.

Then my wallet cried! I knew what I wanted to do with this rifle long before I purchased it so I just made the leap and ordered a whole heap of parts I wanted to not only make it more accurate but improve ergo's some (not that the M14 isn't ergonomic in factory form).

Order went in and all this crap started showing up on my door over the past week!

Troy MCS Chassis

Magpul PRS Stock

Magpul MOE Grip

Yankee Hill Bipod Adaptor Plate

Harris 9-13" Bipod (non swivel, I'm a cheapass

AUKMONT 45º BUIS (cheap, supposedly decent, if not, they'll get tossed)

Sparrowhawk Dummy Selector Lockout kit

Vortex Viper PST 6-24x50mm EBR1 Mil First Focal Plane (Not Pictured)

Vortex Tactical very high rings (yay?) (Not Pictured)

Checkmate Industries 20 round Mags w/ Magpul 7.62 Magpuls x3

Springfield Armory 10 round Mag

Sadlak Industries National Match Spring Guide

Fulton Armory Gas System Shim Kit

Just waiting on the optics to show up and then I might be done... Thinking about throwing the Sadlak Industries National Match gas piston in there too but we'll see how it shoots first when the optics get here.

And for the gun pr0n!

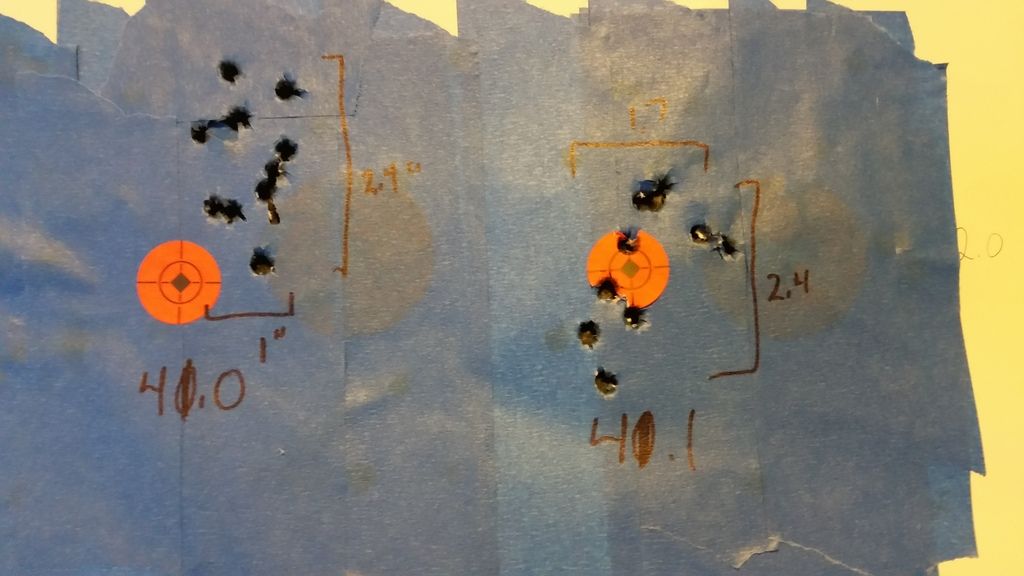

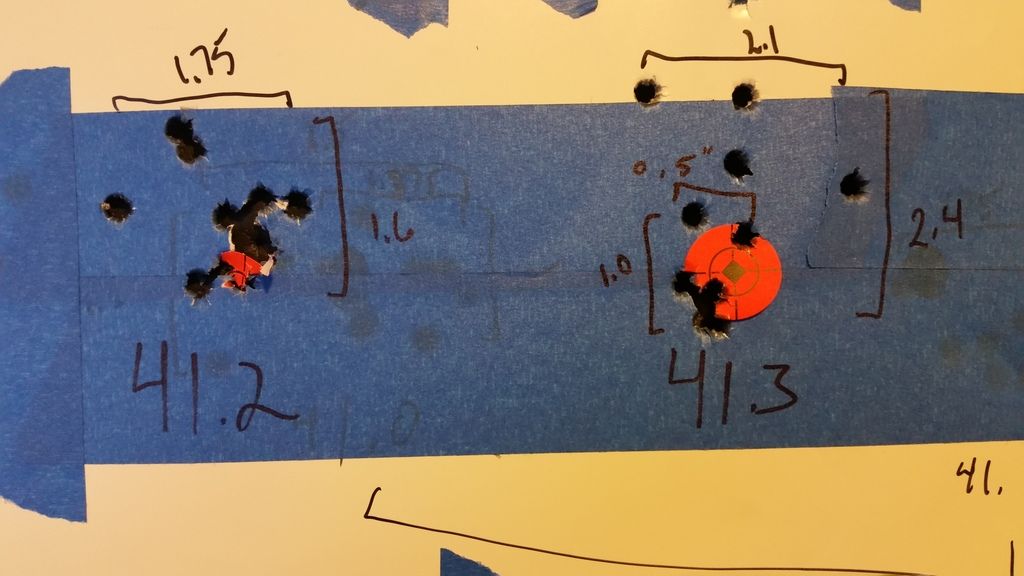

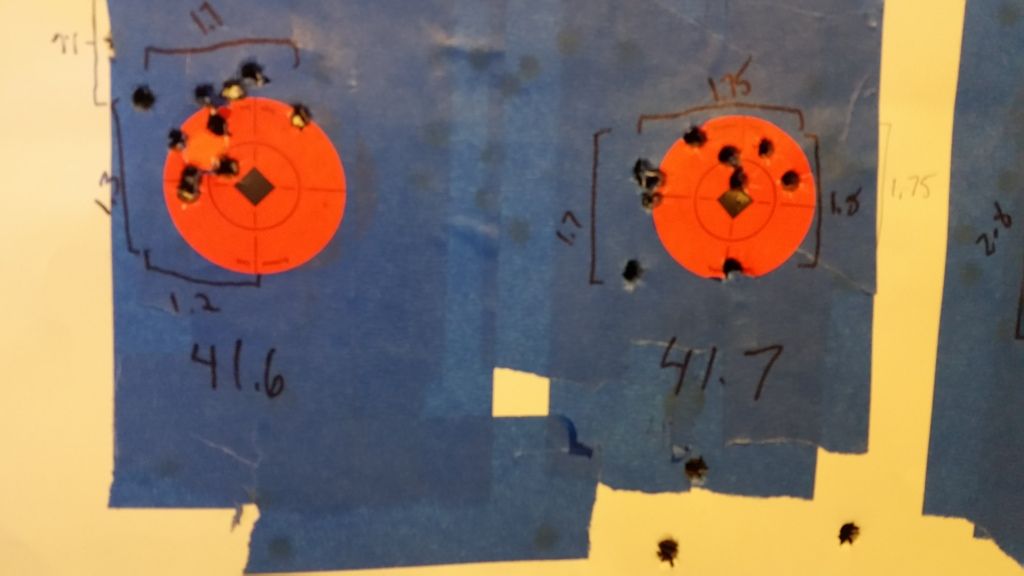

Vortex has been a bit slow in processing my order so I'm hoping that gets here before the end of the decade. I've got some more of the CBC to shoot from the same lot number as the first batch of 50. I'm praying for 2 MOA in this configuration with military ball. I've also loaded up some hand loads using 168gr SMK's and 175gr SMK's (my favorite rounds!) on top of some Varget (kept the loads pretty low, knowing this is a less than ideal powder for M1A's) in the Winchester and CBC NATO cases. I have some comercial Winchester brass around here too that I'll eventually load up and let the brass muncher work it's magic on them. I can't wait for the scope to get here though so I can do more shooting!

Stay tuned for "more"!